The project upgraded Bazis, comprehensive furniture design system. It is a solution that covers the entire life cycle of furniture, from order to delivery

Bazis Center integrated the C3D geometric kernel as the core of the Bazis CAD modules. This decision was key to the product’s success in the furniture design software market.

Customer: Bazis Center is a leading developer of CAD/CAM solutions for furniture manufacturing and related industries, as well as software for furniture distribution centers.

Major business lines:

- software development

- training and consulting in furniture manufacturing process automation

- cloud-based IT infrastructure for furniture distribution.

Official website: https://www.bazissoft.ru

Industry: CAD/CAM/PDM, ERP

C3D Labs Products:

- C3D Modeler

- C3D Converter

Challenges:

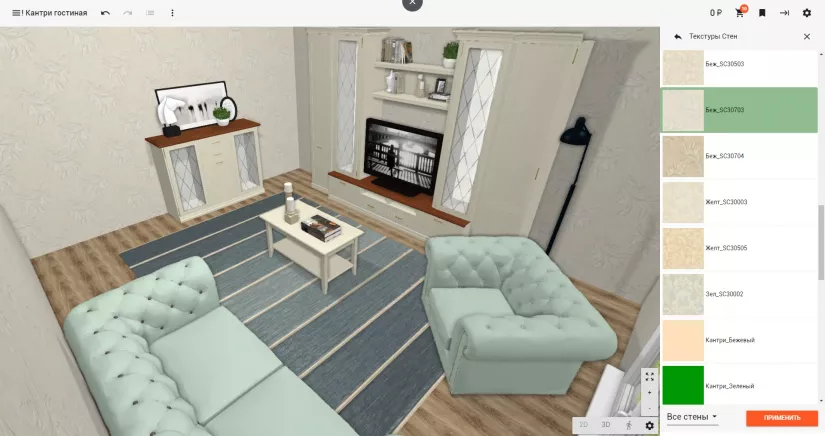

- interior modeling and furniture arrangement on the fly while the client and the designer discuss the job

- visualization of multiple design options for the client to agree on the price, functionality, and lead time

- easy modeling of curved components and complex shapes with many ornamental cutouts

- precise modeling of plane/edge form milling

- fast, accurate modeling of non-standard decorative elements and fasteners

- comprehensive model analysis in the early stages of design to reduce costs and manufacturing errors.

Results:

- Bazis, a domestic integrated furniture design platform

- Over 70% of Russian furniture manufacturers use the system; international customers in more than 30 countries

- The platform now covers not only furniture manufacturing, but also woodworking, construction, and some other industries

- Updated, enhanced Bazis with more precise geometric modeling and visualization.

"12 years ago, Bazis became one of C3D Labs' first customers. Back then, we were just starting to bring the C3D kernel to the market, there was no technical documentation available yet, and no refined tech support", says Oleg Zykov, Director, C3D Labs. “Realizing all this, our colleagues appreciated our potential and believed not even in the product, but in the product team. We are very grateful to them for this and their continued support over the years."

Focus on Customization

Bazis-Center is a reputable furniture design software vendor. The company operates in Russia and the ex-USSR countries. The company’s flagship product is Bazis. Its Release 1.0 was first deployed on PDP-compatible mainframes in 1988. The company continued to improve the software and expand its functionality. In 2005, a 3D kernel was added to Bazis 7.0.

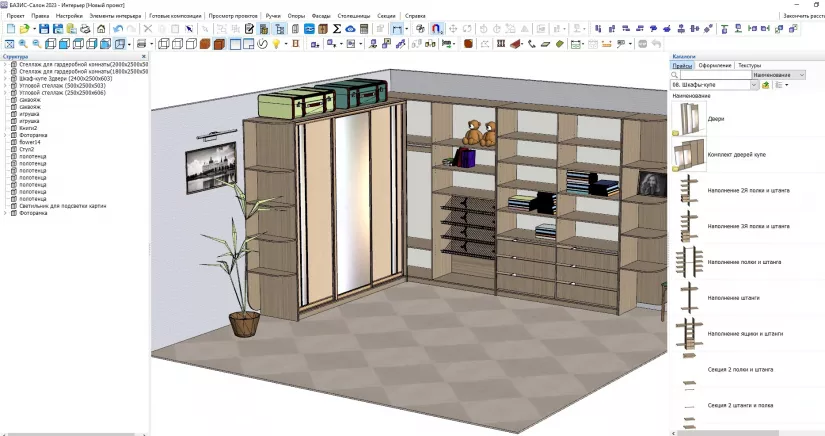

The system is designed to be an end-to-end tool for furniture manufacturers. It covers furniture design, nesting problems, warehouse management, NC programming, and interior design. As the system has evolved, it has expanded to include sales.

As reported by Roslesinforg Agency, in 2023 the furniture sales in Russia reached RUB 455.1 bln. Consumer surveys show that 25% of Russian customers prefer custom-made furniture. Standard models and mass production are being phased out. The users are increasingly interested in products tailored to their personal preferences. Responsive to customer demands and market changes, Bazis-Center focused on build-to-order production. A competitive CAD should be precise, high-performing, and create realistic interior renderings.

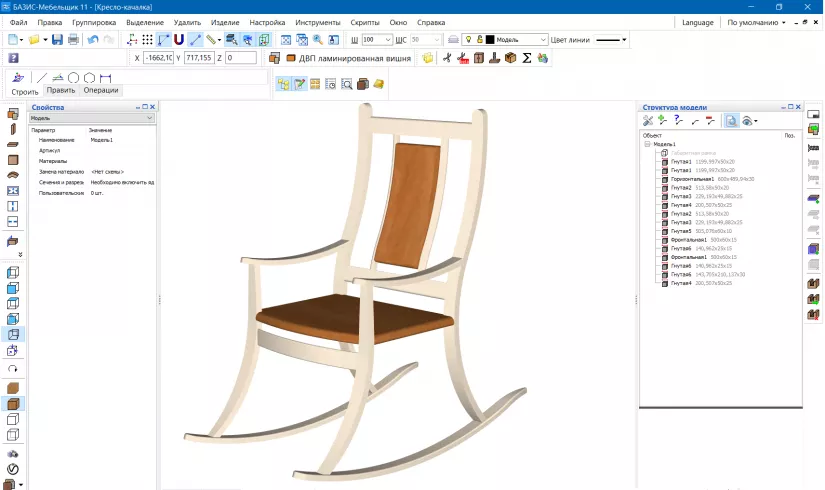

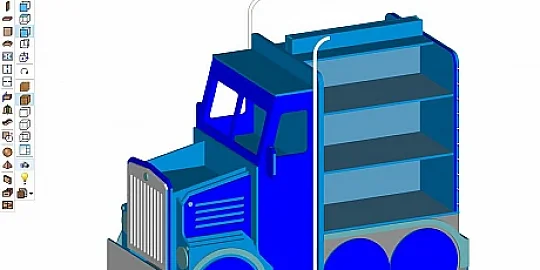

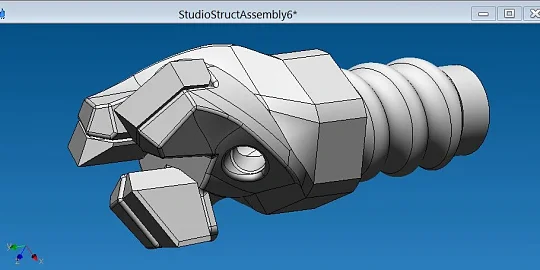

As the customer and designer discuss the order, they arrange the furniture on the fly, considering the visualized interior options in terms of price, functionality, and delivery time. It should also be easy to model curved, non-standard geometry with multiple shaped cut-outs, fancy decorations, fittings, and other complicated components (balustrades, columns, carved decorations, stained glass, etc.), shaped milled plates, and edges. Efficient model analysis algorithms should be applied early in the design process to reduce product costs and minimize manufacturing defects.

Such updates to the base software could only be implemented by adding a 3D model editor with high-quality rendering capabilities. Any 3D editor uses an in-house or third-party geometric kernel. The company needed to choose the right kernel to turn its base product into a comprehensive furniture design and engineering solution.

First Among the Equals

Initially, Bazis used the in-house CSG kernel. Gradually it evolved from a 2D editor to a 3D modeling tool. The vendor decided to replace it with a third-party kernel. Offers from both market leaders and startups were considered. The candidates included Parasolid, ACIS, CGM, Granite, Open Cascade, Solids++ and SMLib libraries, and the Russian C3D kernel. The candidate kernels were tested for half a year to evaluate their pros and cons.

Solids++ and SMLib were initially excluded because there were no CAD systems based on these kernels. The remaining kernels were compared in terms of functionality, performance, and price. The test evaluated such features as accuracy of object location in 3D, ability to model existing and future cabinet furniture components, 3D to 2D conversion, rendering performance and quality, software reliability, and price. Another aspect was the vendor’s ability to make custom modifications to the kernel, as none of the kernels fully met the specific furniture design requirements.

Parasolid, ACIS, CGM, and Granite offered extensive usage history and excellent optimization achieved over decades of operation. These kernels are feature-rich and their prices do not meet the expectations of predominantly small and medium-sized furniture companies. In addition, the large vendors were not willing to modify their general-purpose products for the specific customer. The Open Cascade kernel offered extensive functionality and was suitable for many reasons, but was rejected due to technical incompatibility.

The C3D kernel better suited the Bazis system and became the winner. The kernel supports all basic objects and operations for modeling cabinet furniture. The “furniture” tests showed excellent stability and high performance. The kernel is used on tens of thousands of workstations running the KOMPAS3D CAD system. It also has a clear roadmap with well-defined, achievable goals. Another benefit is the seamless transition to C3D for end users, with no disruption to their workflow. The C3D Labs team was more than willing to support Bazis Center and make any industry-specific changes as early as the pilot testing phase. The price policy was another important factor. The low base price for the rich functionality that outperformed the competition and the minimal cost of upgrading the base software to the new kernel confirmed that it was the right choice.

Overcoming Challenges, Striving the Best

The Bazis software is written in Delphi, while the C3D kernel is a set of C++ classes for B-Rep definition of 3D models, helper classes, and algorithms implemented as global functions. For compatibility, an intermediate interface DLL library was developed in C++. The library uses abstract classes that can be directly used in Delphi because they contain a pointer to the VMT table and the format of this table is identical in MSVC and Embarcadero compilers. Each function in the library meets the principles of object-oriented programming. The DLL exports just one function which returns the main interface.

For furniture modeling, the C3D kernel should construct basic bodies from the input data and triangulate the geometry for subsequent visualization. Bodies are created using the ExtrusionSolid and EvolutionSolid functions. BooleanResult performs Boolean operations in 3D to combine the bodies. The resulting object is a MbSolid body that contains a B-Rep body definition (MbFace faces, MbEdge edges, etc.) A problem arose at this point: performance on complex, multi-body models without caching was unacceptably low. C3D Labs' math software engineers solved the problem immediately. They reprogrammed the construction functions for the most common solids.

After the bodies are constructed, they are visualized using the OpenGL library. At this point, another issue arose. Visualization of textures is critical for furniture models, while C3D did not support texture coordinates. This was not an issue for manufacturing, construction, and other industries, but modeling furniture with rich decorations was impossible without extensive texture functionality. The C3D team managed to overcome this problem as well. Now the C3D kernel can generate parametric coordinates for triangles and calculate scaling factors for each face to apply realistic textures. Also, new procedures to merge textures on adjacent faces were added.

The most time-consuming part of the integration was the modeling of curved front panels that are often used in furniture today. There were several issues to be resolved. First, the kernel lacked body deformation operations, had no option for direct modeling of milling operations (3D mill movement along a curve), and no tolerance control. Second, the kernel sometimes failed when performing operations on bodies with ruled surfaces. Third, there were accuracy problems, as the furniture industry requires a much higher modeling accuracy than other industries. The C3D team guaranteed that all these problems would be solved. Some of them were fixed immediately, and the rest over time.

At the end of the C3D integration into the Bazis software, import/export, body relative position analysis, and other features were added. Bazis Center purchased one of the first licenses of the kernel. The integration project and testing revealed issues such as API and 2D function inconsistencies, etc. All of them were promptly resolved by both partners.

New Capabilities, New Goals

With the switch from the in-house to C3D kernel, Bazis Center solved many problems at once in a relatively short time. The feedback from the Bazis users confirmed that the C3D kernel is an excellent foundation for building special-purpose CADs

Key project results:

- saving time previously spent on the development and maintenance of the proprietary kernel

- better quality of the geometry, correct curved surfaces and edges

- auto-generation of top-class drawings, hidden lines removal

- export/import to common 3D formats (STEP, SAT, X_T)

- realistic modeling of arbitrary furniture and interior elements (profiles, balustrades, stairs, etc.)

- any operations with curved panels, editing of the panel outline and its elements

- modeling of any furniture decor and fittings

- machining of grooves with arbitrary cross-sections; the cross-sections are automatically added to the detailed drawings

- model verification for panel collisions and fastener locations.

The collaboration between the Bazis Center and C3D Labs teams resulted in the Bazis software with the C3D kernel. The new product is a leading CAD tool for furniture businesses. The platform evolves according to furniture fashion trends, emerging technologies, new materials, fixtures and fittings, and user feedback. The collaboration with C3D Labs, the developer of the active geometric kernel, will continue.

"We are passionate about expanding and updating the Bazis platform, striving for the ideal. We consider the smallest nuances of the customer workflow, their immediate needs, and the challenges they face," says Mikhail Fedorov, Chief Technology Officer, Bazis Center. The switchover of the CAD modules to the C3D geometric kernel has made it possible to add several important functions that were previously unavailable, such as the unique ability to build local cross-sections. Visualization quality has improved significantly and is a priority as the models are on display for potential clients. Both furniture manufacturers and distributors highly praise the new solution".